Powering ferries with floating PV, hydrogen

Hydrogen system components on a ferry

Image: Universiti Malaysia Pahang Al Sultan Abdullah, Energy Conversion and Management: X, CC BY 4.0

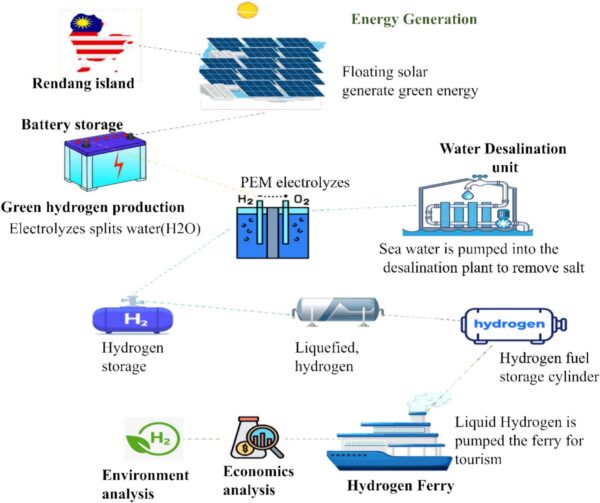

A research team led by scientists from Malaysia’s Universiti Malaysia Pahang Al-Sultan Abdullah has simulated and conducted a techno-economic-environmental study of a system that utilizes offshore floating solar PV with hydrogen production for the fueling of small ferries. As a case study, they have analyzed the 250-passenger ferry that goes from Malaysia’s Terengganu to Redang Island, covering a distance of 60 km per round trip.

“This is the first comprehensive study to assess the feasibility of using offshore floating solar to produce hydrogen for short-distance ferry operations in Southeast Asia,” Sudhakar Kumarasamy, the corresponding author, told pv magazine. “While offshore renewables and electrofuels have been studied separately, this research uniquely provides a comprehensive techno-economic-environmental framework that covers the entire value chain—from offshore solar energy generation, seawater desalination, hydrogen electrolysis, liquefaction, storage, and ferry refuelling logistics.”

The system’s simulation was mainly carried out on PVGIS24. It included a 20 MW floating PV plant, consisting of 40,000 solar panels, each rated at 500 W. They are placed at a 10° tilt angle and south-facing orientation. It uses a lithium-ion battery storage system of 12 V and 100–200 Ah per unit. It powers a seawater desalination unit that is fed into a PEM electrolyzer to create hydrogen. The hydrogen is stored in Type III cylinders, and the bunkering station utilizes shore-to-ship transfer. The bunkering infrastructure requires 260 kW for a daily capacity of 500 kg.

Schematic

Image: Universiti Malaysia Pahang Al Sultan Abdullah, Energy Conversion and Management: X, CC BY 4.0

The Redang Island, where the simulation was carried out, has a tropical climate with a temperature of 27 C to 29 C and humidity of 74% to 86%.

Solar irradiation is 5.003 kWh/m² per day, with an average wind speed of 10 km/h and a rainfall of 2,600 mm per year. Capital costs were estimated at RM 4-5 million ($950,600-$1.2 million) per MW of floating solar, RM 3–4 million per MW of PEM, RM 1–1.5 million per tonne of hydrogen storage, RM 250,000–400,000 per MW of desalination system, and a total of RM 8-12 million for the refueling station. The discount rate was assumed at 6% and the project lifetime is 21 years.

“The study shows that a 20 MW offshore floating solar system can generate about 637,619 MWh of solar electricity, annual CO₂ reduction of 23.75 million kg and about 12,892 tonnes of hydrogen over its lifetime,” Kumarasamy added. “The hydrogen production closely mirrors solar irradiance patterns, with peak production during April-May (around 58,000 kg/month) and significant drops in December (35,665 kg/month) – a variation of about 60%. The volume reduction from gaseous hydrogen (up to 24,000 m³) to liquefied hydrogen (around 850 m³ peak) – roughly a 96% volume reduction – demonstrates the critical importance of liquefaction for practical maritime storage.”

Furthermore, the results indicated that the system can support approximately two round-trips per day. It results in a levelized cost of energy (LCOE) of RM 0.276/kWh and a levelized cost of hydrogen of RM 13.64/kg. “That is higher than conventional fuels —but still competitive considering the lifetime emission reductions and energy density benefits of e-hydrogen and within the projected global benchmarks set by the International Energy Agency (IEA) for green hydrogen by 2030,” Kumarasamy concluded.

The results appeared in “Offshore floating solar with electrofuels for refuelling small ferries: a techno-economic-environmental study,” published in Energy Conversion and Management: X. Researchers from Malaysia’s Universiti Malaysia Pahang Al-Sultan Abdullah, India’s ICFGS Foundation, Manipal Academy of Higher Education and the Maulana Azad National Institute of Technology have participated in the study.